Arch Systems

Operational Intelligence

from the Top Floor to the

Shopfloor, and Back Again

Product Design

User Research

Sales & Marketing Support

Analytics

A.I.

Background & Problem

Electronics manufacturing lines rely on continuous operation of SMT, assembly, and test equipment. Successful, global manufacturing organizations rely on close coordination and responsiveness across many different roles, operating in tight concert. Teams often lack:

- Real-time visibility into performance issues or machine stops

- Inconsistent root-cause investigation methods, leading to high variance across shifts

- Accessible, actionable workflows to help operators quickly triage and resolve downtime

- Standardized KPIs across lines and sites

As a result, downtime events are discovered late, resolution is inconsistent, and overall equipment effectiveness (OEE) underperforms.

Team & Role

Working with a team of 2-4 PM's, the Head of Product, broader leadership, engineers, data scientists & key client stakeholders, my role was to rapidly iterate interactive prototypes and stand up a scalable design system designed to improve detection, response, and performance outcomes across multiple strategic & operational personas (below), along with AI touchpoints throughout to assist and bridge workflow.

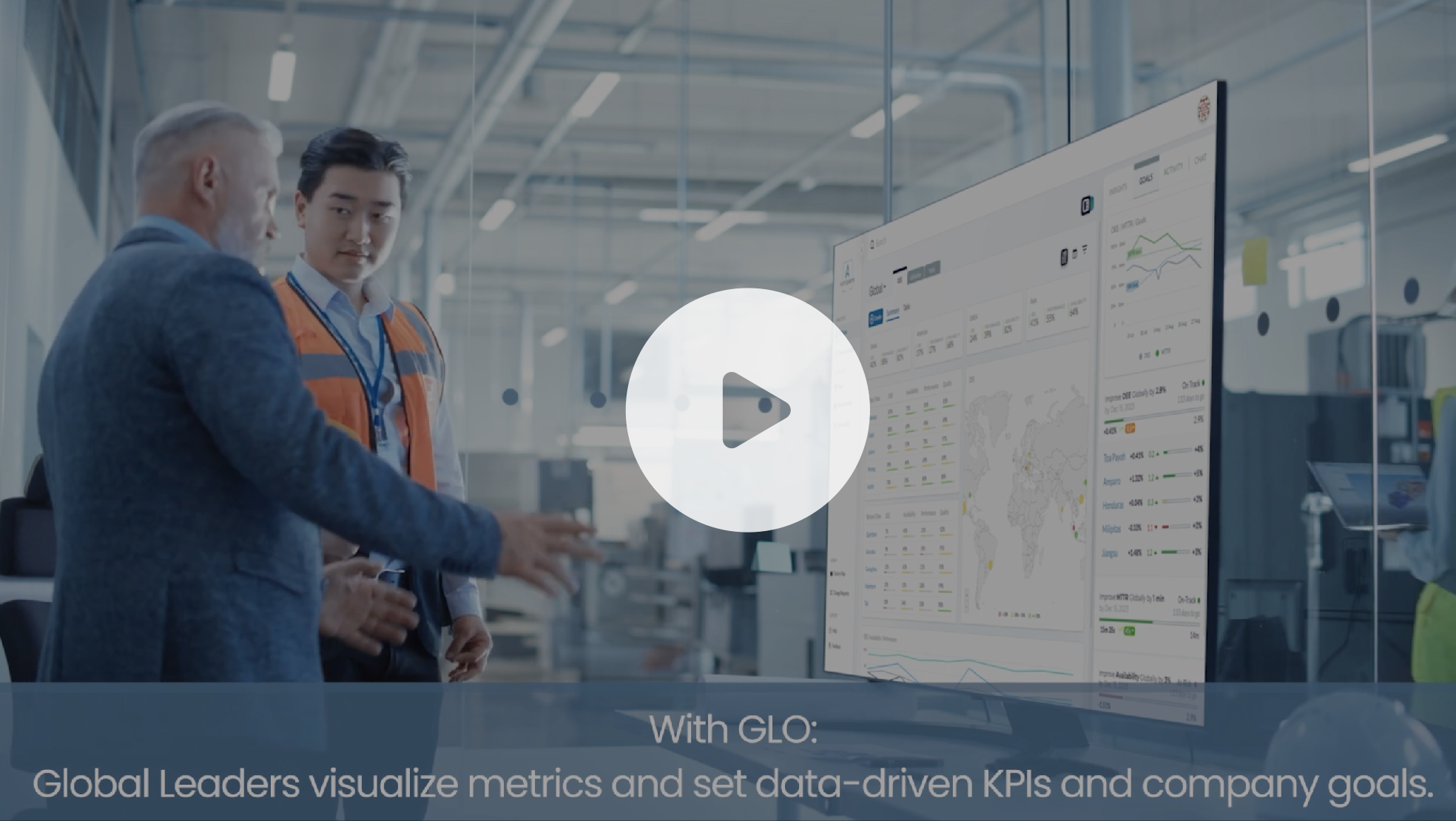

This was achieved through the transformation of Arch FX, GLO and Process Insights into a core, seamless, efficient experience.

Target Users & Their Needs (consolidated)

| User | Line Operator | Shift Manager | Engineering Teams | Site/Area Managers | Global Ops & Executives |

|---|---|---|---|---|---|

| Pain Points | Doesn't always notice machine performance degradation immediately; troubleshooting varies by machine | Difficult to prioritize where attention is needed across the floor | Incomplete or inconsistent incident context | Consistent metrics & KPIs for analyzing performance | Understanding the impact of widescale decisions on local contexts |

| Needs | Immediate alerts, simplified decision-making, guided steps | Cross-line visibility, prioritization of active issues | Standardized logs, data-rich issue reports | Sophisticated breakdowns of KPIs and trend insights leading to plans of action | Tracing impact of global success initiatives on local performance |

Proposed Solutions

Unify Arch's core applications (Arch FX; GLO KPI Sets; React – Real-time Machine Event Detection; Action Manager - Guided Resolution; Process Insights) under a common, core experience supporting end-to-end downtime resolution, operational performance reporting, and progress towards organizational goals.

Information Architecture

- Moving from a "30,000 foot" global view into line-by-line, chip-by-chip granularity, efficiently routing users to root-cause insight, means first organizing around a navigational hierarchy mapped to various data models & schema throughout a diverse network of connector types and B.I. data inputs.

- Breadcrumbs and navigational tree menus assist display of the current hierarchichal context, making it easy to dive in and back out.

- This was one of the "first things first" initiatives to support Arch's continued expansion into global manufacturers, including the 2nd and 3rd largest in the world.

- Top-level hierarchy:

Global (all Sites)

↳ Site

↳ Area

↳ Line

↳ Machine / Device

Role-based access, filters & views

- Today, compliance and general security best practices are grounded in principles of zero trust, least privilege and RBAC (Role-Based Access Control).

- Accessing tools across various levels supporting corresponding user personas within a common UX framework --one which results in dev sprint efficiency and design economies of scale-- required hierarchy- and entity-specific tooling tailored to the role of the user.

- Transforming a suite of independent products with unique interfaces into a cohesive, scalable offering meant inlaying these product features throughout a RBAC'd hierarchy.

Global (all Sites) GLO KPI Sets

↳ Site GLO | Process Insights (PI)

↳ Area GLO | PI | Action Manager

↳ Line GLO | PI | React | Action Manager

↳ Machine / Device PI | React | Action Manager

Macro/Micro Side Panel

- Preserving "macro", high-level perspective and real-time analytics while examining the "micro" minutiae of any given situation --and vice versa-- helps you assess root cause and take context-rich, highly-specific action in full understanding of the impact on bigger picture items.

- A side panel which mirrors the active position in the hierarchy, or can be toggled to operate independently, can assist & accelerate alignment when conveying nuance and presenting to colleagues.

- Maximized efficiency via optimal planning and savvy resource allocation requires contextually-nuanced priorization sometimes only having the full picture right in front of you can enable.

- Empowering team members to act with information typically beyond their reach compounds the value of their focus & attention. Through freed up strategic support and intelligently teed up tactical touchpoints, chaos becomes symphony.

In-context Toolbar & Modal access

- Many features are necessary across tools and roles, but accessing them intuitively can be complicated without the aid of fixed toolbar, where users know they can consistently go to analyze different dimensions of what information they are looking at.

- Figuring out "where it should live" is the fun part of research, experimentation, and collaborative iteration. Through multiple rounds of research, our team developed a deep understanding of a user's day-to-day, their workflows, and what friction points they encounter disrupting the "flow" in their work.

- The consistent position of the toolbar relative to other primary actions on the screen is key to developing natural & rote-intuitive interactions with minimal cognitive load (often what results in "delight"). When a user's mind is freed up to maintain momentum of thought towards the task or complex situation instead of navigating distractions of bolted on UI, transformational, higher value-added work can be achieved more easily and consistently.

- While not always the best solution, modals accessing discrete applications can dramatically simplify reaching a solution, taking action, and jumping to the next priority (especially as a "system of systems" integrating a vendor ecosystem).

AI assistant

- And then there was "Zero UI": language, our original interface.

- At the end of the day, if it's badly broken, even the most sophisticated action plan will route you to the manufacturing equivalent of the 'Owner's Manual' (read: 100s and 1000s of pages... somewhere...).

- LLM's and AI Models opened the door for radically accelerating if not simplifying troubleshooting, translation, and summarization.

- I was in charge of leading the design effort for weaving in these AI touchpoints and seed prompts throughout our UX, as well as ideating some of the initial applications to research and prioritize in order to maintain our competitive edge.

Results

- Within 4 months, one global EMS saw machine availability improve 140%, from 19.6% to over 48%, along with a 97% improvement in OEE across SMT lines using Arch

- Millions saved in avoided costs due to decreased downtime across clientele

- User satisfaction increased across user types

- Accelerated sales cycle

- Top-tier client acquisition & market expansion